Acrylic solid surface sheets, admired for their exquisite blend of aesthetics and durability, undergo an intricate production process that transforms raw materials into masterpieces of modern design. In this exploration, we will delve into each nuanced step of the acrylic solid surface slabs.

Process 1: Raw Material Preparation

For middle to higher markets, we are always careful about the selection of raw materials. Super pure aluminum powder, chosen for its structural integrity, high-quality PMMA renowned for its optical clarity and impact resistance, and we use imported pigments to infuse vibrant colors—all contribute to the foundation of this solid surface sheets production. The emphasis on selecting top-tier materials sets the stage for the exceptional quality that will be evident in the final product.

Process 2: Proportion and Commixture

Precision is the heartbeat of this phase. The raw materials, now carefully curated, are proportioned according to an intricate formula. The blending process unfolds on specialized mixing equipment, and the pouring of the mixture is executed with meticulous care. The duration of the mixing process is calibrated to achieve flawless homogeneity, a critical factor influencing the material’s overall performance.

Process 3: Pouring and Molding

The homogenized mixture is then poured into molds, and the shaping of these sheets begins. Skilled craftsmen guide the pouring process, ensuring an even distribution of the material within the molds. The molds themselves play a pivotal role in determining the final shape and structure of the sheets, lending a touch of craftsmanship to the otherwise acrylic solid surface process.

Process 4: Baking in a Homothermic Temperature

The molded sheets embark on a transformative journey within homothermic chambers. Subjected to specific temperatures for a predetermined duration, this baking process is elemental in solidifying the material. It grants the acrylic sheets their stability, strength, and resistance to external factors, making them a robust choice for various construction applications.

Process 5: Polishing – Panel by Panel

The solid surface stone emerges from the baking process with potential waiting to be revealed. In the polishing phase, each panel is treated in predefined polishing machines. Skilled workers oversee this delicate procedure, ensuring that every inch of the surface receives the attention needed to achieve a good finish.

Process 6: Thickness Determination and Polishing

First, the thickness of each sheet is measured with precision instruments. Any variations are addressed through further polishing, guaranteeing a uniform thickness across all sheets. Moreover, ESHINE SOLID SURFACE always has positive thickness, so that the customer still has enough thickness after the later processing.

Process 7: Edges Trimming

In our factory, advanced machines will trim and shape the edges of each sheet with meticulous precision. For customers to save more time and processing costs

Process 8: Drying under Hot Wind

Hot winds envelop each slab, ensuring a complete and uniform drying experience. This automated step not only optimizes efficiency but also contributes significantly to the overall quality of the final product. The controlled drying process enhances the material’s characteristics, making it ready for the subsequent phases of inspection and packaging.

Process 9: Full Inspection One by One

A responsible attitude and strict quality control procedures define this critical phase as each sheet undergoes a meticulous inspection. Every nuance, from surface finish to thickness uniformity, is scrutinized. Quality control measures are stringent, reflecting the commitment to delivering flawless products to all of our customers.

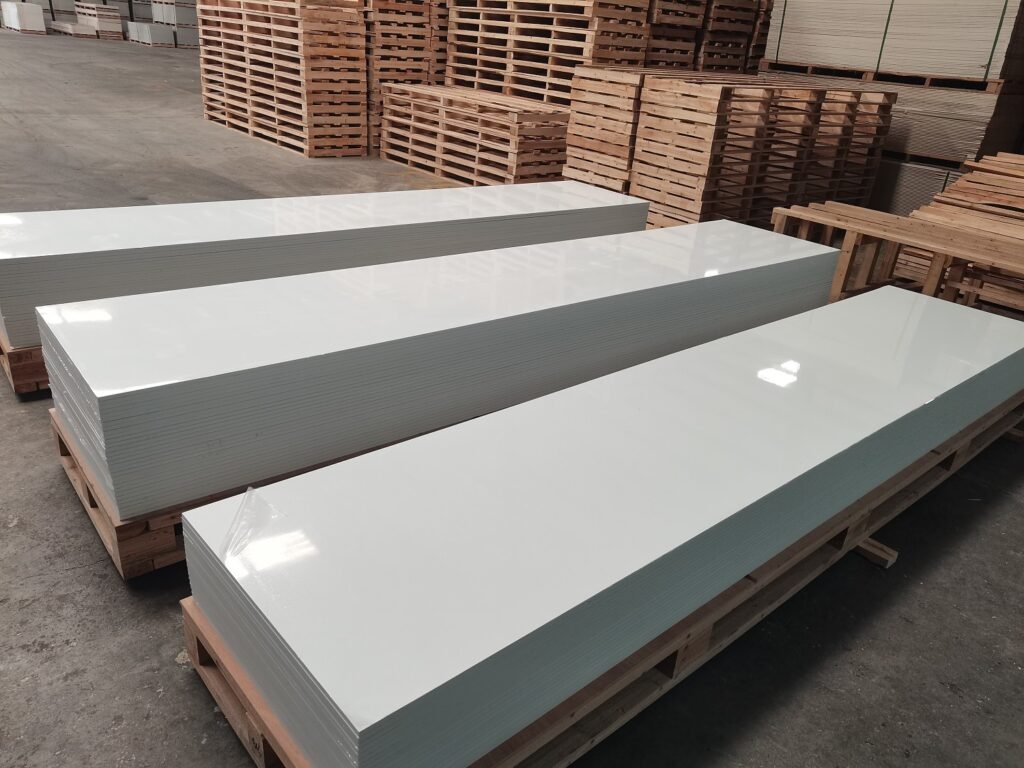

Process 10: Packing in a Seaworthy Shipping Way

With quality assured, the solid surface sheets enter the final stages of preparation. Each solid surface slab is carefully packed using a seaworthy approach, designed to withstand the rigors of transportation. The packaging not only protects the sheets but also reflects a commitment to sustainability, and ensuring that the products arrive at your warehouse perfectly.